Clive has been involved in ceramics for over forty years, He has exhibited widely in the UK and abroad.

Sometime in the mid-sixties, not long out of National Service, two friends persuaded me to join them at pottery evening classes; I was reluctant, having never considered ceramics. The venue for the classes was very well equipped and tutored by a man called Hugh Ford, a clever and experienced teacher. Having made one or two clumsy attempts at producing something in clay, which were fired and transformed into durable glossy objects, I was fascinated. I came to love working with clay and found that I had a reasonable talent for it.

Even now after many years the various smells of a pottery and all its various bits and pieces I still find evocative. The time came, after exhausting the possibilities at Duke Street Norwich, to move on. The idea of a formal ceramic course held no appeal having recently given up two years of my life to my country! I left my day job, became self employed and moved into a remote cottage where I could create mayhem, work late into the night and not disturb neighbours.

It was quite difficult combining work with learning the difficult art of throwing but after a year or two, I arrived at a level of skill that enabled me to become a full time potter. It was a lovely but impoverished time. I absorbed everything I could about ceramics, going to seminars and attending sessions around the country, watching demonstrations by the likes of Mick Casson David Leach, John Leach, Michael Cardew, Ray Finch, David Eales, Wally Keeler and many others. I learnt so much from those very helpful and kind men.

After acquiring some competence I decided to develop a single simple celadon type glaze using, as far as possible, locally dug minerals. This worked very well. I supplied various outlets including the main one which was David Mellor kitchen shops. He was a wonderful person to deal with; encouraging, firm and settled accounts scrupulously and if things were a bit tight occasionally, would make an advance. I made utilitarian wares for fifteen years. Working in this tight parameter I honed my skills but also I wanted to explore and stretch my creativity. The chance to live in the Dordogne for a year came up so, with the family, I packed kit and bags and wended down. This was a wonderful time for me; time to experiment, time to drift, to think, visit friends, enjoy the cuisine, and the glorious countryside.

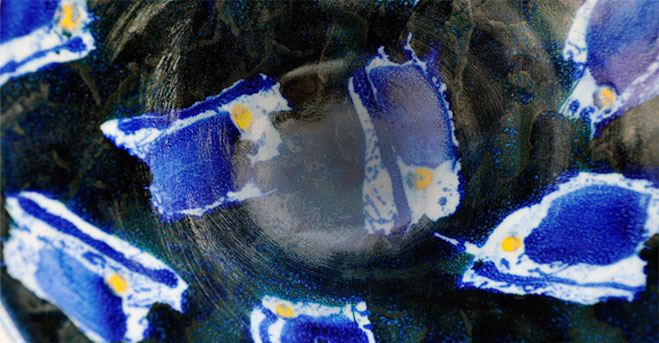

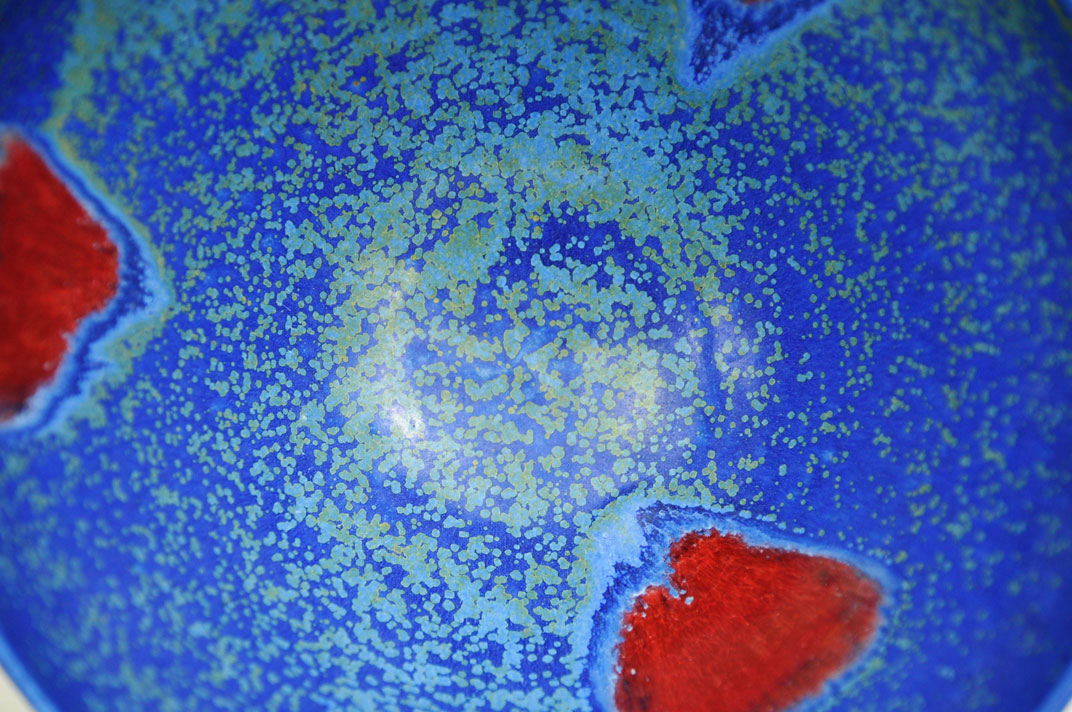

On returning to Suffolk I decided on radical changes and started experimenting with various oxides and clay bodies. I was a little tentative at first but was greatly encouraged after visiting an exhibition by Sutton Taylor which was a wonderful display of swirling colours. This greatly helped to loosen inhibitions. Janice Tchalencoe published her new found glazes one of which I still use. I have managed over the years, with endless tests, to gain some control over my glazes. I enjoy the ability to make them run and merge, creating a third tone, or making them stiff and static. Currently I produce a much narrower range, preferring to work more with ‘one off’ pieces such as large dishes, bowls and jugs, some of which are illustrated.